High Performance Materials Business

“Zero Thermal Expansion” – The ultimate alloy material strongly supports the application of high precision required in modern technology

Our High-Performance Materials Development Business offers LEX-ZERO® to solve thermal expansion issues that inevitably occur in the manufacturing process. LEX-ZERO® is an alloy material that achieves the ultimate zero expansion. It is the ultimate solution material that can solve not only the recent challenges to meet the application of high precision in products, but also for solving more advanced issues that are expected in the future.

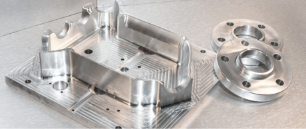

In addition to LEX ZERO®, we offer a wide variety of LEX® series products with different thermal expansion properties. Materials can be formed in dimensions ranging from centimeter level to over 2 meters through casting, machining, and 3D laminate modeling.

The scope of applications extends from the global environment to the space environment. We also provide tailor-made alloy designs to solve thermal issues for our customers.

Business sectors and industries of main customers

Industry

- Semiconductor industry

- Production equipment manufacturers and device manufacturers who need solutions for thermal expansion.

- Measuring and analytical instruments, telecommunication equipment industry

- Manufacturers who need solutions for noise reduction and sensitivity improvement of optical instruments.

- CFRP and FRP molding industry

- Aircraft, automotive, and other related manufacturers that use molds.

Departments

- Departments mainly involved in equipment development

Please feel free to contact us if you are facing issues with thermal expansion in the manufacturing process.

Main Applications

-

Semiconductors and Flat Panel Display

- Semiconductor manufacturing equipment (e.g., wafer lapping and polishing machine, CMP, stepper)

- Semiconductor inspection equipment (probe card)

- Flat Panel Display tools (Deposition tools)

-

Machine tools

- Machining center

- Precision multi-spindle drilling machine

- Precision grinding machine

- Precision press machine

-

General dies and molds

- General dies and molds

-

Measuring and analytical instruments

- Laser measuring instrument

- Special microscope

- Three-dimensional measuring instrument

- Precision flowmeter

- Particle sensor

- Liquid chromatography

- Metal analyzer

-

Telecommunication equipment

- 4G/5G base station equipment

-

3D additive manufacturing

- 3D additive manufacturing for machining

Do you need solutions for your issues?

- Improve the machining accuracy of manufacturing equipment by eliminating the fluctuation of accuracy caused by thermal expansion by heat.

- Solve reduction of accuracy and yield loss caused by thermal expansion

- Solve thermal issues and review equipment design (thermostatic chamber, cooling system, etc.) from a zero-based perspective

- Use a 3D printer to form shapes that are impossible with machining

of JFE Shoji Electronics has solutions

LEX-ZERO®

Our low-thermal-expansion material LEX® series including the ultimate zero-expansion LEX-ZERO® solves the thermal expansion issues that arise in our customers’ manufacturing processes. LEX® series also has superior machinability and is available in general-purpose block material (400 X 400 X 150 mm) ready to be delivered to our customers. We will cut them to the desired size.

Complex shapes that could not be achieved by conventional machining can be formed with 3D additive manufacturing . Lost- wax casting with high near-net-shape characteristics is available in large quantities.

Higher accuracy

The product accuracy is easily maintained and the original design performance can be demonstrated by suppressing thermal expansion fluctuations due to temperature changes. This enables customers to improve the accuracy of their manufactured parts.

Improvement in stability and yield

Less influence of thermal expansion ensures stable product accuracy, which contributes to the improvement in factory productivity and yield.

Cost reduction by eliminating temperature control equipment

Temperature controlling system and room will be unnecessary or downsized for maintaining production accuracy. This achieves improvement in the manufacturing process and reduction in costs.

Flexible equipment design is possible

The elimination (or downsizing) of temperature control devices allows flexible mechanical equipment design.

3D printers enable the manufacturing of products that was not possible with conventional machining.

With their high modeling capability, 3D additive manufacturing can create complex shapes that could not be formed with conventional machining methods. They remove issues in forming round, triangular, and rectangular shapes to allow designers to create designs with unprecedented flexibility.